Services

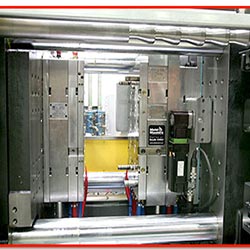

Injection Molding

At MDI, we provide quality molding services that include plastic molding, plastic injection molding, and medical injection molding services.

Insert, Over molding and Two-Shot Molding

Insert molding is a process that requires an insert, typically metal, to be pre-placed in the tool for injected plastic to flow around.

Dip Molding

Dip molding is the process of dipping a mold into a polymer to create a molded component.

Dip Coating

The dip coating process entails the submersion or spraying of a product with polymer or coating solution.

Blow Molding

When manufacturing hollow plastic parts, the blow molding process is utilized. There are three main types of blow molding.

Spray Coating

Spray coating offers an alternative to dip coating for specific coating applications, products and polymers.

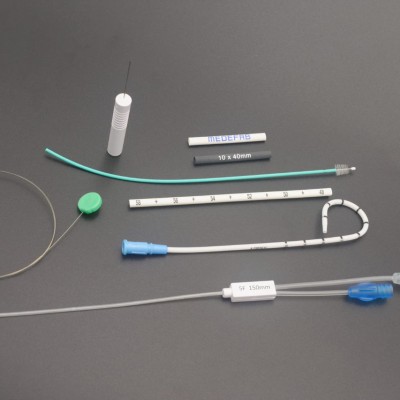

Tube Extrusion

MDI has a wide-range of capabilities in custom extrusion. Specializing in flexible to semi-rigid PVC.

Clean Room Molding & Assembly

Our team at MDI is ready to help you process and assemble any of your medical devices, no matter how simple or complex

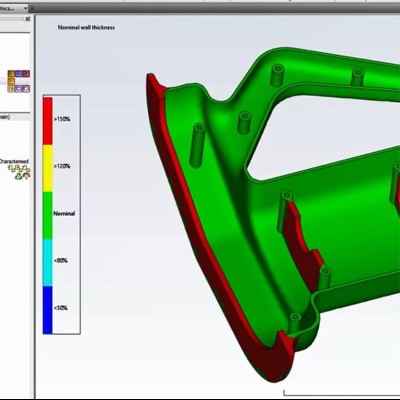

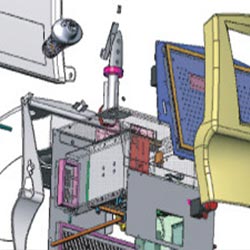

Engineering & Tooling

It’s one thing to create a beautiful aesthetic design but another to be able to take that design and engineer it for production

Equipment Building

We can also assist your company with the selection and comparison of various polymers, process optimization and tooling development to advance your project to the next level.

Ultrasonic Welding

This is a very fast, efficient and reliable method of joining plastic parts and components with a durable, lasting bond.

Part Marking and Decorating

With over 50 years in the Medical Device Industry, MDI uses Class VI Medical Grade and Biocompatible inks.

Product Design and Development

It’s one thing to create a beautiful aesthetic design but another to be able to take that design and engineer it for production

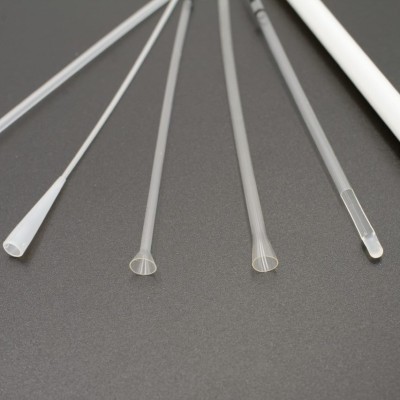

Flaring and Tipping

MDI’s custom tip forming equipment can quickly and repetitively provide smooth, accurate transitioning for all your invasive devices.

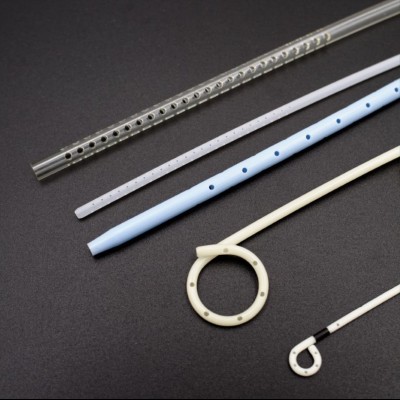

Micro drilling

MDI’s custom-built drilling equipment, can provide you with clean holes in any configuration, straight line or spiral pattern hole drilling, or punching.

Sterile Barrier Packaging

Achieving and maintaining the sterility of medical devices is one of the main challenges facing the industry. This is where packaging systems play crucial role.

Wire Assembly

Mexico’s manufacturing industries, especially in aerospace, automotive, electronics, and medical devices, are known not just for the lower costs but also for the quality of production.

UV and Solvent Bonding

Medical Device Bonding. Light curable and solvent medical device adhesives possess the reliability demanded by the medical market.

Cable Harness Assembly Manufacturing

Help organize your cables and wires into a singular unit through our cable harness assembly services. These services help keep large electronics systems organized and safe.

Specialty Gears and Assemblies

Spur Gears, Helical Gears, Worms, Bevel Gears, Pulleys, Threads, Widgets, Frames, Housings.

MOLDED DEVICES INC.

Take Advantage of Our Outstanding Services

For business owners who specialize in the mass production of goods, having the right tools for the job is important. Using the injection molding services we offer can help you get the materials needed to produce thousands of the same plastic products with ease. Our team is able to meet your needs and make a durable plastic injectable mold to ensure you get the finished product you are looking for. We have helped production-based businesses for years by providing them with top-notch plastic molding services.

Product Design and Development Services

Our team also offers comprehensive product design and development services. If you have an idea for a product, our team of engineers will work with you to fine-tune the details of your design. Once you are satisfied with the product design, you can take advantage of our plastic injection molding service. Our goal is to help you take your product idea from concept to completion.

Involve Us Early On

Getting the best results from the plastic molding services we offer is easy when involving us in the beginning stages of product design. Our experienced team of engineers have helped design everything from medical devices to industrial products. When designing a medical device, you will need an experienced engineer by your side to ensure your design can meet FDA standards. Neglecting to get the stamp of approval from the FDA can spell disaster for your medical device, which is why letting our team of engineers advise you during the product development phase is so essential.

Contact us to find out more about the services we have to offer. Our team is here to help you bring your product ideas to life.

HAVE A QUESTION?

WE ARE HERE TO HELP!