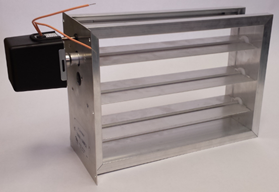

Background: The HVAC industry has been using zone dampers for decades. Behind the scenes, usually above ceiling tiles in office buildings or attics in homes, are square or round ducts providing filtered cool or heated air to selected areas of a building to keep its occupants comfortable throughout the day and/or evening. When a leading HVAC zone damper manufacturer approached Seitz LLC to design and build an actuator which was more efficient, powerful, and reliable, we took on the challenge, and developed our own product for the customer.

Seitz LLC The Solution Provider: The team of Mechanical Engineering’s developed what is referred to in the industry as a Spring Return Actuator which has 6.45 times the closing power, 2 times the final closing torque, and 4 times the life than the customer’s current supplier within the same envelop. These performance characteristics are critical to insure the damper, when closed, reliably seals off the air duct when required for HVAC efficiency and noise reduction. You’d think with all of these performance improvements it would have to sell for a much higher price. Not the case. The Seitz LLC Spring Return Actuator is the same sell price as the competitor’s while delivering more value.

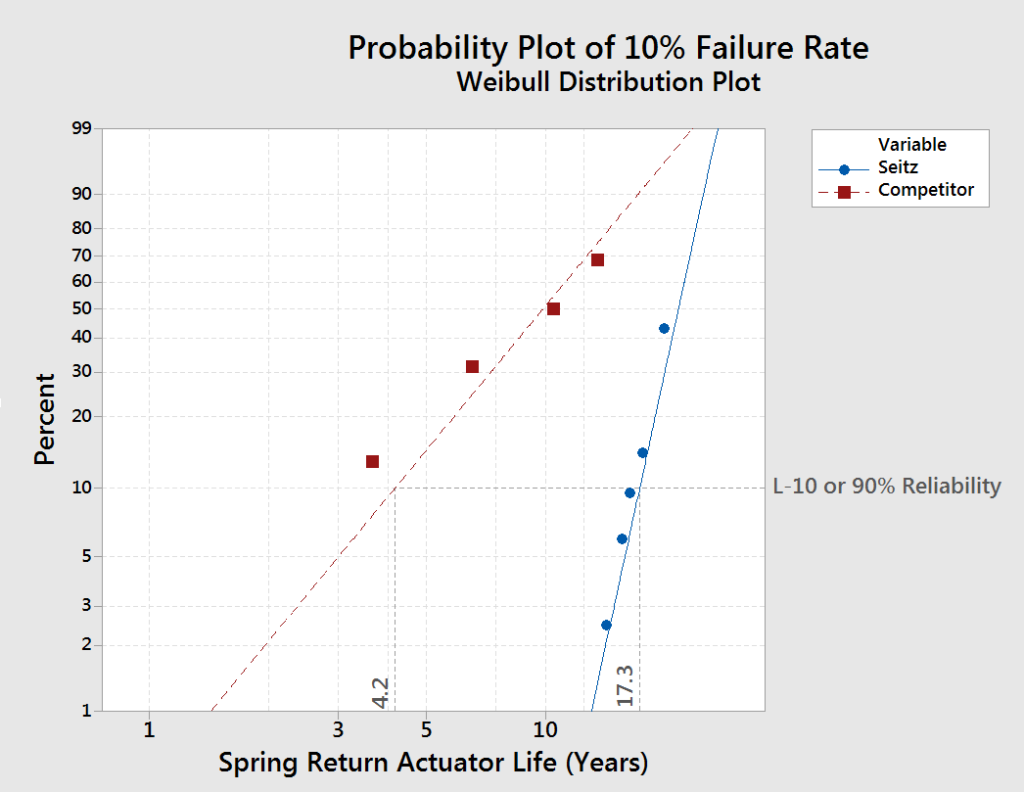

Seitz Mechanical Engineers are trained in reliability testing techniques and very often write and conduct validation testing protocols for our customers. At a typical 20 actuations/day the expected 10% failure rate occurs at 4.2 years (30,660 actuation cycles) for the competitor and 17.3 years (126,200 actuation cycles) for the Seitz LLC Spring Return Actuator. Another noticeable difference between the competitor’s actuator and Seitz LLC is there was no loss of performance characteristics with the Seitz actuator during validation testing. The Seitz actuators maintained all key performance characteristics up to their expected life of 100,000 actuation cycles while the competitors lost more than 50% of their performance over their useable life.

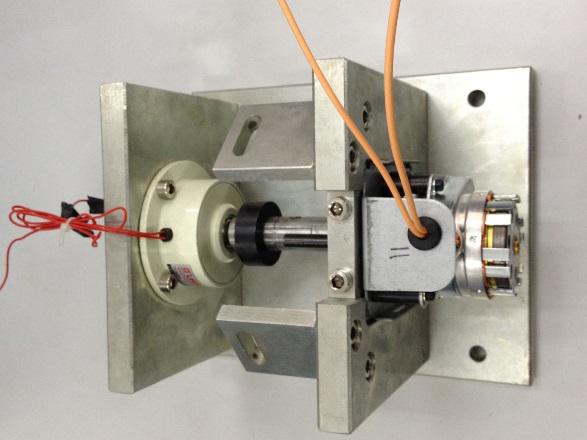

Good reliability of a system doesn’t happen by accident. (30) Production actuators were tested in a Seitz LLC designed and built test stand to failure whereby they were exposed to continual opening and closing cycles. Periodically the actuators were interval inspected to insure they lost no performance characteristics such as: closing power, final closing torque, time to open/close. Separate testing was also conducted in an environmental test chamber to understand if the actuators would have any loss of performance in extreme temperature and humidity conditions (32°F and 150°F at 70% relative humidity).

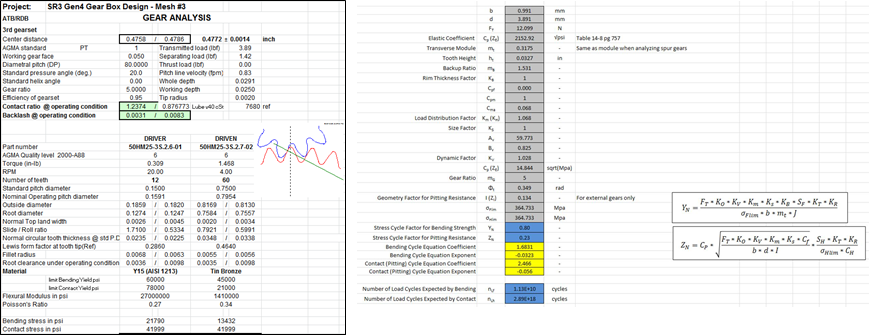

Because Seitz LLC Mechanical Engineers have a diverse industry, materials, and mechanism background, we are able to design and engineer a variety of products and components made from materials other than thermoplastics such as: powdered metal, stampings, TPE/TPU, machined, ground, etc. A good example of this is we were able to not only design plastic gears, but also ferrous and non-ferrous metal gears and predict cycles to failure.

Recent Comments